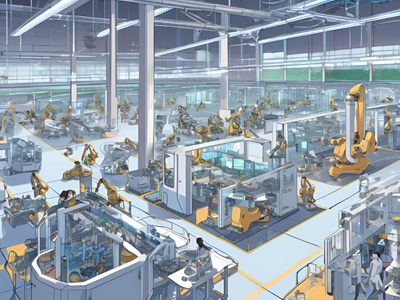

Artificial intelligence integrated into the manufacturing process opens new possibilities for efficiency improvement, cost reduction, and optimisation of production management. On the other hand, integrating AI within the manufacturing processes also requires establishing proper legal frameworks that regulate the use, distribution, and control of these technologies. AI makes it possible to automate complicated manufacturing processes that were impossible before, minimising human error and improving product accuracy and quality. AI-powered analysis of equipment performance data serves to anticipate possible breakdowns and thus helps schedule maintenance that reduces downtime. AI will analyse several supply chain variables to optimise inventory and enhance logistics. Product quality control has gone a notch higher, with AI-based systems monitoring it automatically for defects and incompliances with standards. The creation and utilization of AI software raise intellectual property issues that have to be clearly regulated. This makes sure data processed through AI are not exposed to unauthorized access and usage in light of regulatory requirements like GDPR. Some key ethical standards in implementing AI in manufacturing include non-discriminatory use of technology, lack of bias, and protection of workers’ rights. A positive result of applying AI in manufacturing may consist of imposing considerable gains in productivity and product quality. Yet, the successful integration of AI requires technical innovation and the elaboration of an effective set of legal mechanisms that would ensure the regulation of technology use, protection of data and intellectual property, and determination of liability in case of possible errors or violations. Due consideration for all legal regulation issues will enable AI to express its full potential in manufacturing and minimise the risks that will develop in this respect.